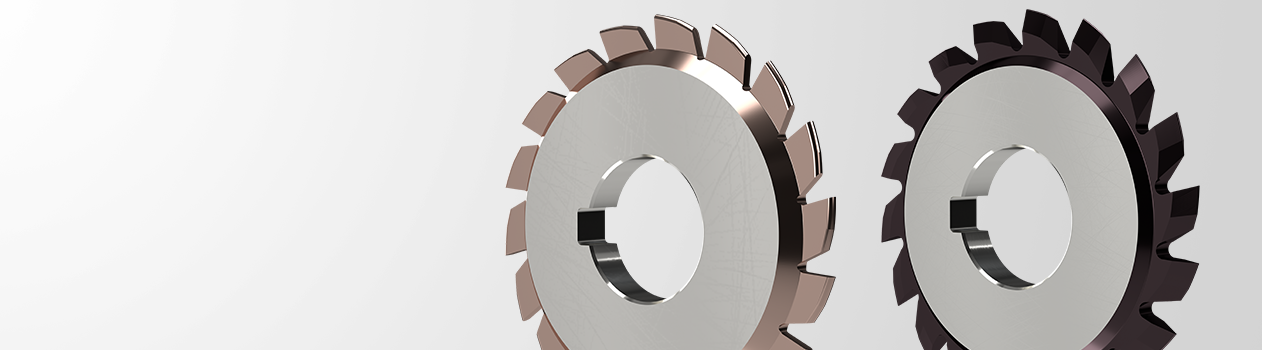

Notched bar impact tests with Kaestner-Tools!

Entire profile with radial relief (appr. 2/3 of tooth has constant profile, can therefore often be sharpened in the chip space).

Complete re-grinding of the profile will thus become necessary only when the teeth have been decreased by 2/3 or if the profile has been deformed > This is cost-effectiveness.

Please note:

According to DIN 148-1 (prev. 50115) high precision with a very tight tolerance is required for notched bars. This is necessary in order for strength calculations of the tested material to be carried out correctly and precisely for statistical evidence testing. In most cases a measuring protocol of the milling cutter is required along with the provision of evidence. In order to provide this high precision to our customers and in order to meet the DIN requirements using the right tools we offer our own in-stock programme of milling cutters for notched bars (including a measuring protocol if required).

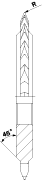

V-Notches

HSS, PM or solid carbide

Notched bar impact testing (Charpy test) acc. to DIN EN 148-1 (ISO/ V)

45°±30' x R 0,25±0,025

Milling depth up to 2 mm

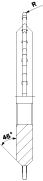

U-Notches

HSS, PM or solid carbide

Notched bar impact testing (Charpy test) acc. to DIN EN 148-1 (ISO/ U and DVM)

Convexe R 1±0,07

Milling depth up to 5 mm

Contact us, your SIMTEK contact person or one of our worldwide sales partners about the possibilities and advantages of high-performance tools from Kaestner-Tools.