simmill 9W

High-performance tool system for groove, slot and parting off milling in two different sizes with milling depths up to 16,5 mm!

The system consistsof high-performance milling tools that offer maximum precision, very high cutting performance and a very long service life, especially for demanding milling operations.

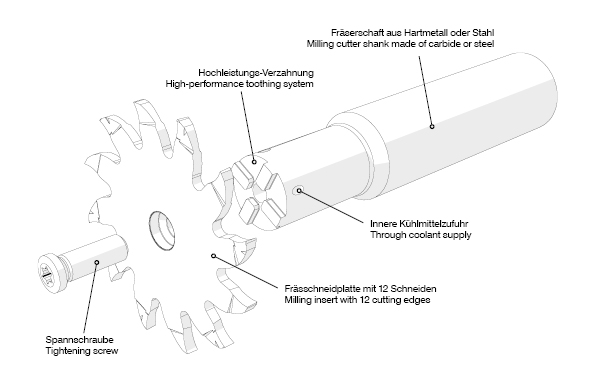

Thanks to a high-performance toothing technology, in which the milling inserts make almost full-surface contact with the base and flanks of the insert seat, simmill 9W transmits very high torques, considerably improves radial and axial run-out and, ultimately, significantly increases the cutting performance.

The high-performance toothing effectively counteracts torsion at the milling insert-toolholder interface. As a result, the toolholders have a very long service life under normal conditions and offer maximum performance, especially when other milling inserts can no longer withstand the high demands.

Milling inserts:

simmill 9W1:

Six-edged milling inserts for general groove milling with cutting diameter Ø 28,0 mm, cutting edge widths from 1,2 mm up to 2,5 mm and milling depths up to 9,3 mm.

simmill 9W4:

Twelve-edged milling inserts for groove, slot and parting off milling with cutting diameter Ø 50,0 mm, cutting edge widths from 0,5 mm up to 6,0 mm and milling depths up to 16,5 mm.

Toolholder:

simmill 9W1:

Carbide:

With internal coolant supply and shanks according to DIN 6535 HA and DIN 6535 HB.

- shank diameters 15.875 mm and 16.0 mm

- usable length of 33,0 mm

Steel:

With internal coolant supply and shanks according to DIN 1835 A and DIN 1835 B.

- shank diameters 15.875 mm and 16.0 mm

- usable length of 20,0 mm

simmill 9W4:

Carbide:

- With internal coolant supply and shanks according to DIN 6535 HA

- shank diameters 15.875 mm and 16.0 mm

- usable length of 60.0 mm / 90.0 mm / 120.0 mm

Steel:

- With internal coolant supply and shanks according to DIN 1835 A

- shank diameter 19.05 mm and 20.0 mm

- usable length of 32.0 mm

MONODULAR - Modular meets monoblock!

simmill 9W closes the existing gap between modular milling systems and monoblock tools because, despite its modular design, simmill 9W comes very close to the performance of monoblock tools - at significantly lower tool costs.

Download the product flyer here and get to know the many advantages of the simmill 9W milling system.

High-performance toothing

The steep flanks of the precision-ground tooth form increase force absorption, stability and precision by a multiple compared to sintered tooth forms. This leads to a a significant improvement in component quality and a longer service life.

The system details:

Video

Experience the tool system simmill 9W4 in a short video.

Further simmill product groups:

Modular tool system including cassettes for using the standard simturn product groups simturn AX and simturn DX as well as compatible adaptors for fine turning heads.