High-precision small part machining with SIMTEK!

For more than 25 years, the SIMTEK Group has been the specialist for precision tools for high-precision small part machining.

With around 5,600 standard tools for internal machining starting with a minimum diameter of 0.3 mm up to a minimum diameter of 24.5 mm as well as for external machining with shank dimensions from 10.0 mm x 10.0 mm on, SIMTEK Präzisionswerkzeuge GmbH offers the right tool for almost any application in small part machining, combined with high process reliability, repeatability and performance.

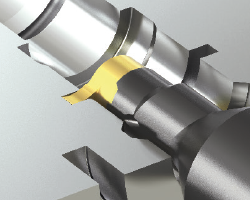

Especially the tool system simturn AX, developed and introduced by SIMTEK in 1998, is designed for maximum performance and stability and allows great performance in smallest bores as of Ø 0.3 mm.

Overview of high-performance tools for cost-efficient small part machining.

PDF, 16 MB

High-precision small part machining tools!

Great performance in smallest bores as of Ø 0,3 mm.

Very precise and strong tool system of solid carbide cutting insert and steel toolholders. High repeat accuracy from insert to insert and usable lengths up to 9xD! For best performance in bores as of Ø 0,3 mm.

More than 3.000 standard items provide the right answer for almost every internal turning application.

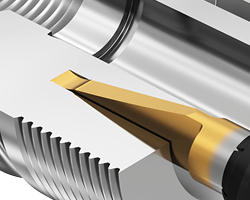

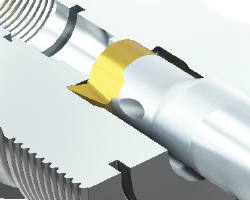

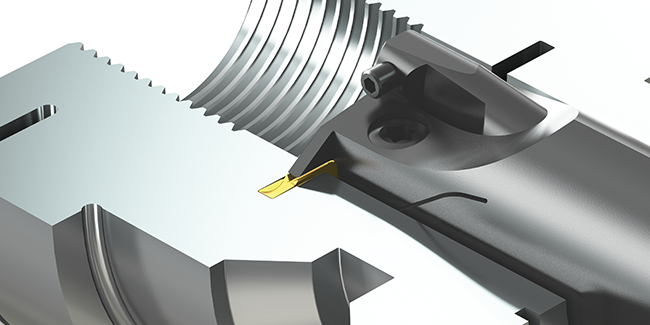

Great performance in bores as of Ø 7,0 mm. Available in 11 different sizes.

Wide range of carbide cutting inserts, fixed with a screw on the toolholder front side. Anti-vibration carbide and steel toolholders are available for a variety of applications.

Available in 11 different sizes, for best results in bores between Ø 7,0 mm and 22,0 mm. More than 2.000 standard items provide the right answer for almost every internal turning application.

Grooving

Boring

Copying

Grooving and Profiling

Threading

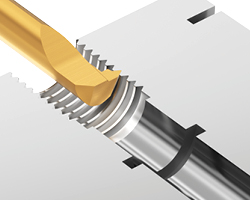

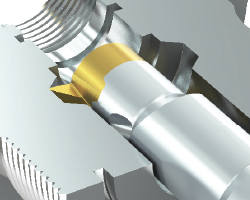

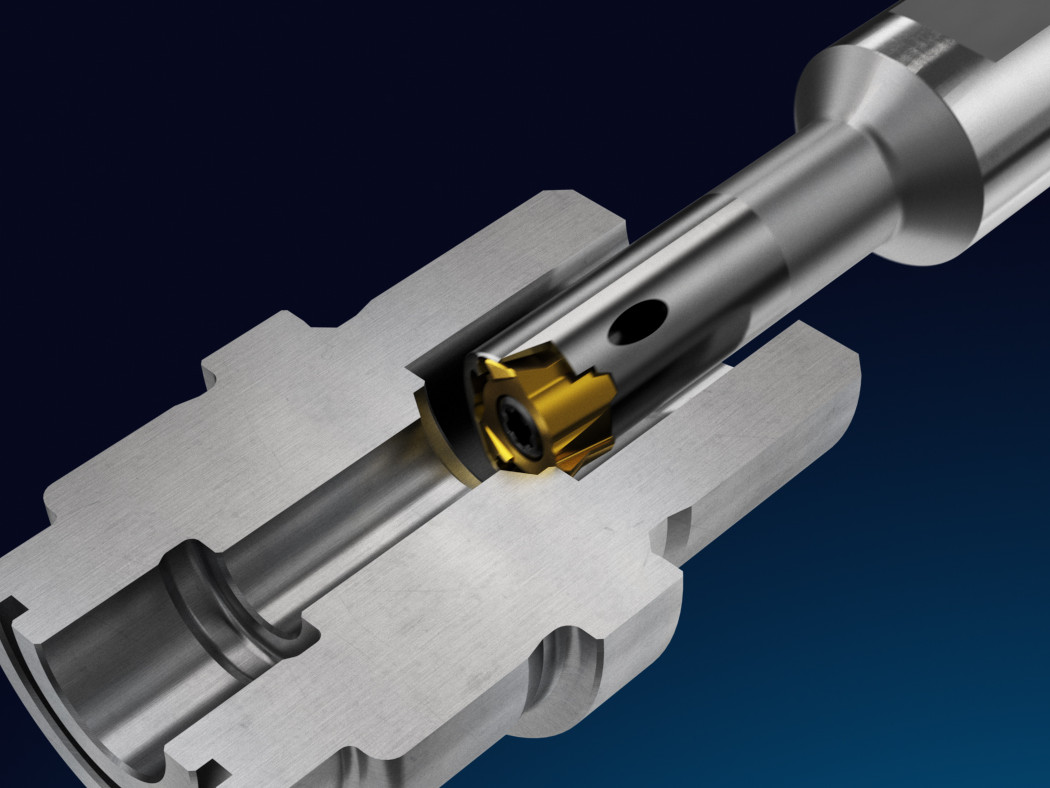

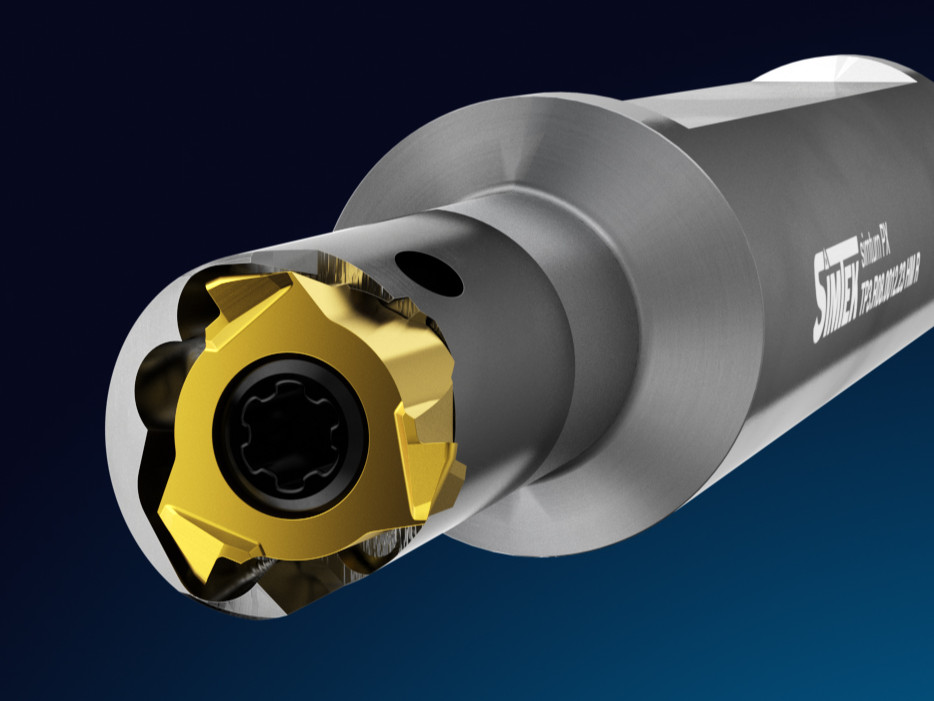

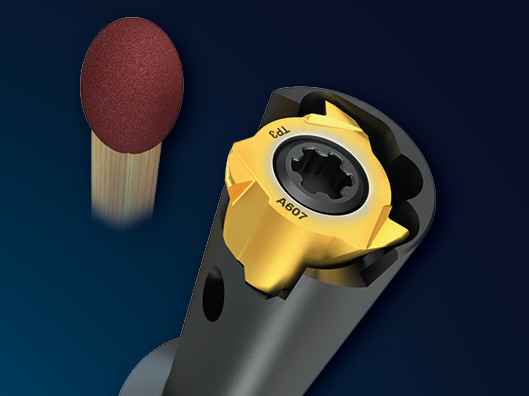

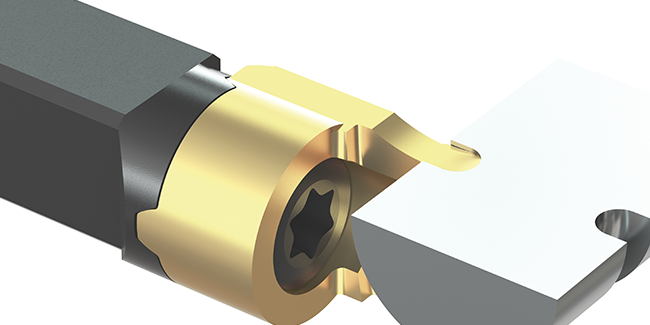

Boring reinvented! Three ground cutting edge for the boring of bores starting at Ø 7,8 mm.

Triple-edged, precision ground indexable cutting inserts with very high repeat accuracy for boring applications star-ting at Ø 7,8 mm - with maximum price/performance ratio! The front-side insert mounting allows a tool change within the machine and thus, together with a self-centering insert seat, offers easy handling and the possibility to consider-ably reduce non-productive times. In addition, a special protective area effectively protects the two passive cutting edges from damages during the machining process.

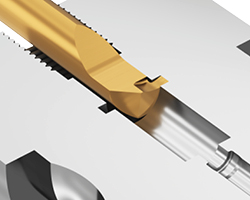

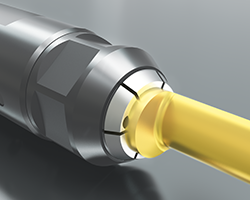

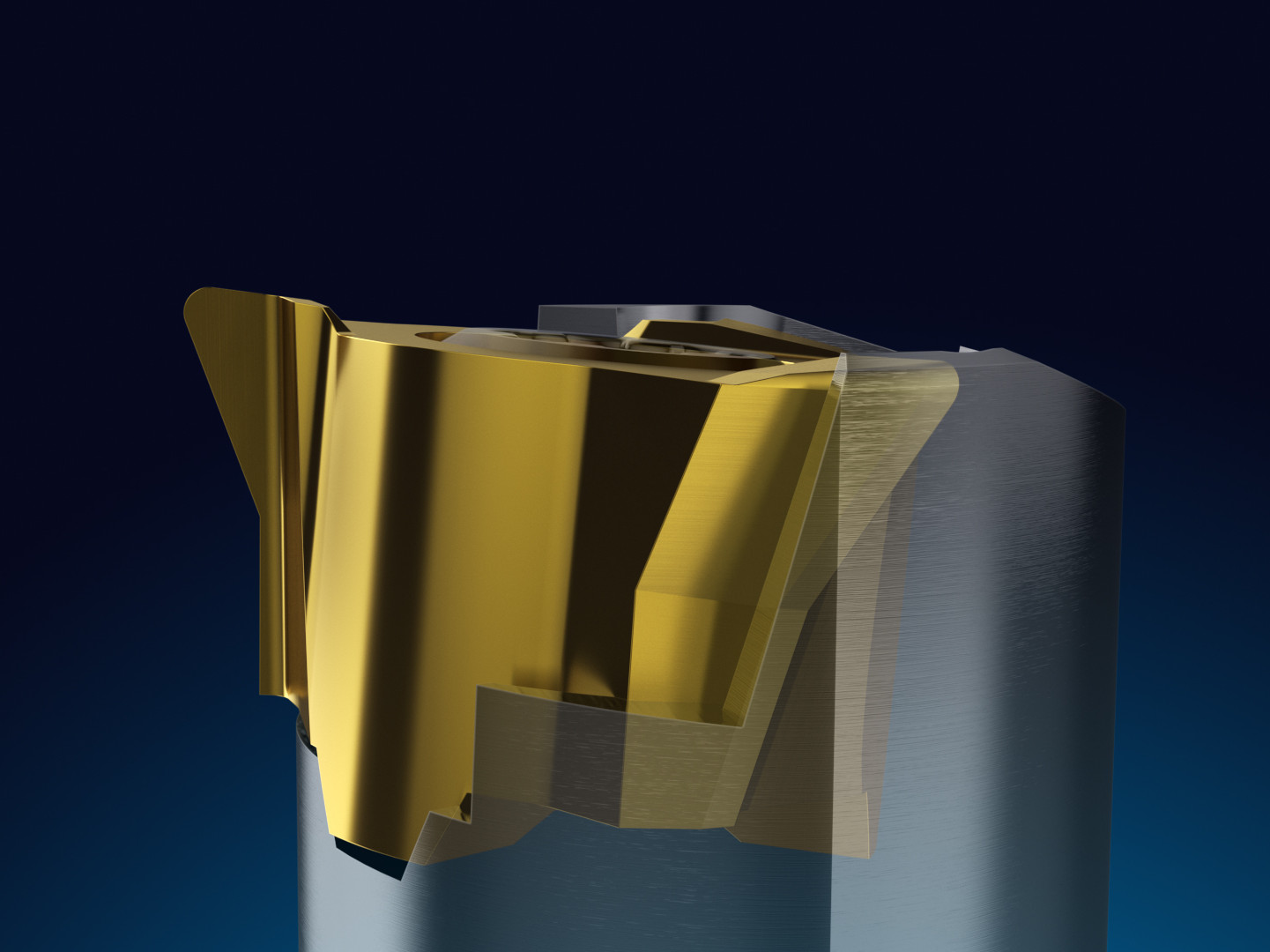

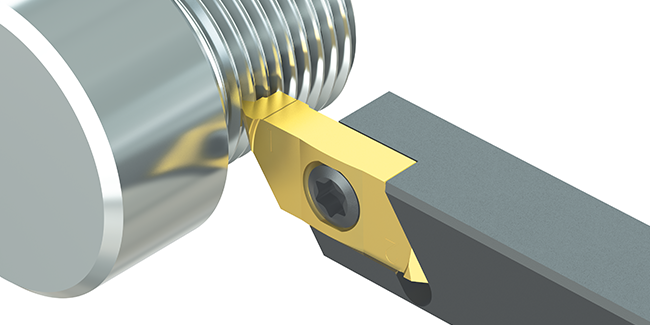

Tool system of double-edged carbide insert and steel toolholder. For use in bores as of Ø 24,5 mm.

The cutting insert and especially the cutting edge was designed to offer best chip control and improved performance in bores.

The special insert seat design enhances the overall stability and cutting force absorption and leads to improved results.

Grooving

Profiling

Parting off

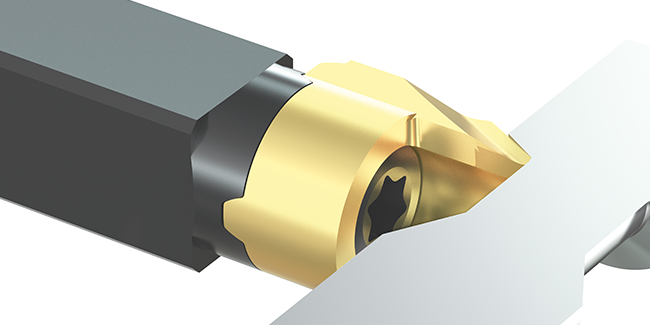

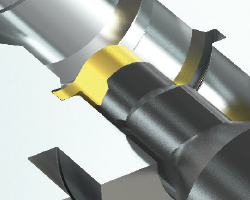

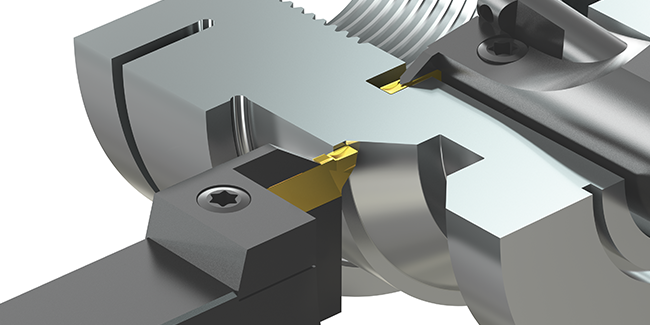

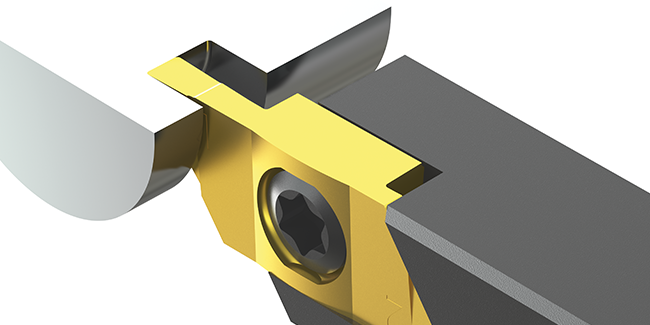

The tool system simturn K2 was designed to meet highest expectations in Small part machining. The system provides two-edged indexable cutting inserts and square shank sizes from 10x10 mm on. All the major applications are available as standard items providing cutting depths up to 7,0 mm.

Grooving

Turning

Threading

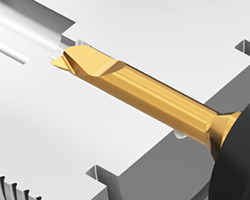

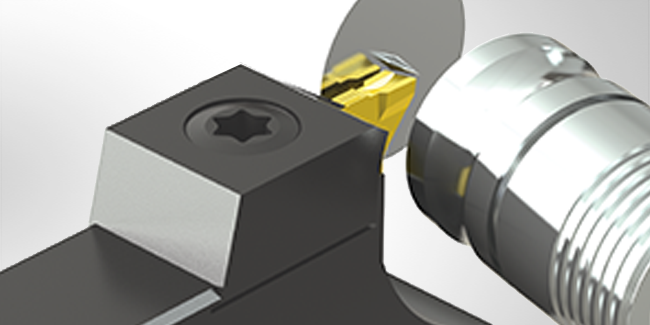

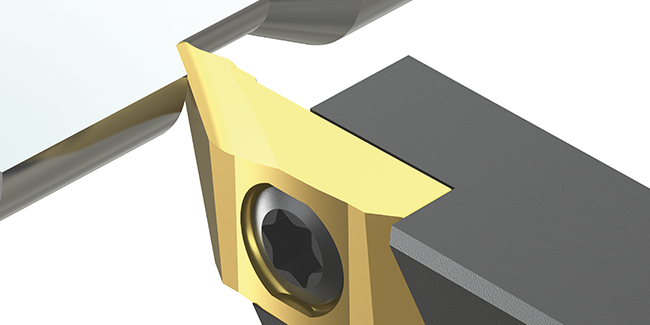

The tool system simturn C4 was designed to meet special requirements in Small Part Machining:

It provides an easy-to-use solution by mounting inserts from the front-side, along with shank sizes starting from 7,0 x 7,0 mm on.

All the major applications are available as standard items providing cutting depths up to 5,5 mm.

Grooving

Turning