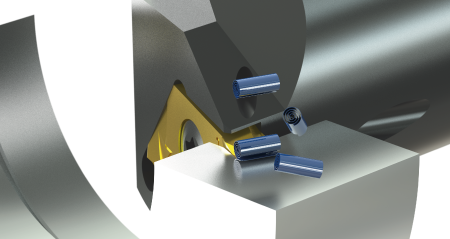

Exemplary SIMTEK individual tools for highest chip control.

Process-reliable chip control

Process-reliable chip control can be a decisive factor for the success of a component production. Particularly in the area of SIMTEK individual tools, special emphasis is therefore placed on a chip forming geometry that is ideally adapted to the machining process in order to optimize chip form, chip breakage or chip evacuation.

Contact us for a individual tool solution tailored to your individual needs!

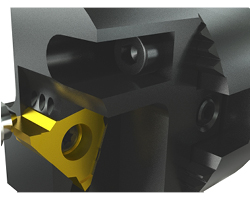

3D-lasered chip forming geometries

The use of 3D-lasered chip forming geometries increases the process reliability and cost-effectiveness of your machining. In addition, complex requirements and combination tools can be implemented cost-effectively with 3D-lasered chip forming geometries.

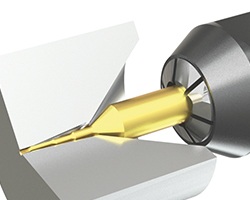

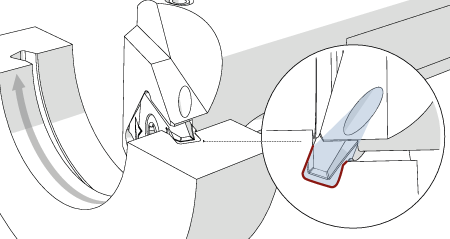

Optimal chip breaking

Non-productive time is reduced thanks to optimum chip breaking and the addition of precise coolant flow under the chips. This eliminates downtime caused by the removal of the chips and leads to fewer scrapped parts because of poor surface finished or damages caused by uncontroled chips.

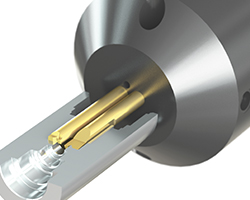

> simturn KX

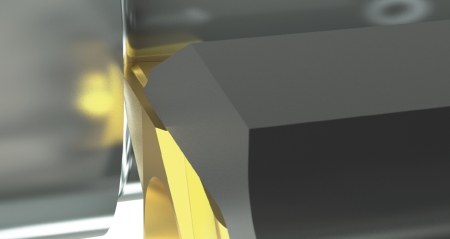

Increased chip control

Increased chip control and controlled chip breaking thanks to the chip forming geometry, perfectly matched to the material to be machined.

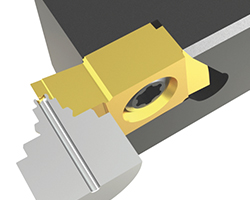

> simturn FX

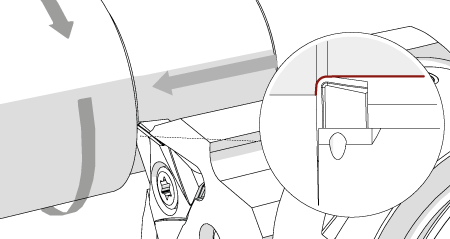

Process-reliable chip control

A chip forming geometry ideally adapted to the machining process leads to optimum chip control, breaking or removal.