The brand for high performance tooling solutions for drilling, countersinking, reaming or milling operations.

As a specialist for rotating tools, Kaestner Tools is dedicated to providing high performance tools with high precision, reliability and competitiveness. The tooling range contains tools for drilling, sinking, reaming, milling as well as special- and combination tools.

SIMTEK offers you the complete range of products from Kaestner-Tools and, of course, also individual solutions specially adapted to your individual needs and machining conditions.

Talk to your SIMTEK contact person or to one of our worldwide sales partners about the possibilities and advantages of high-performance tools from Kaestner-Tools.

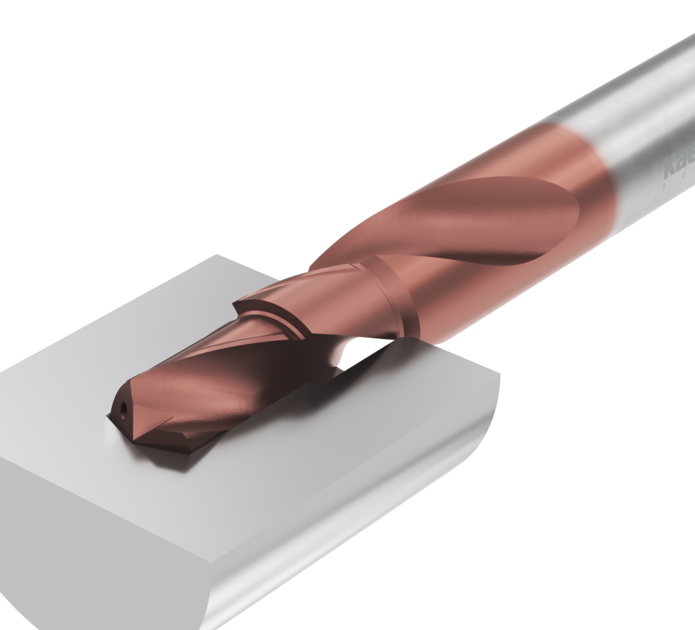

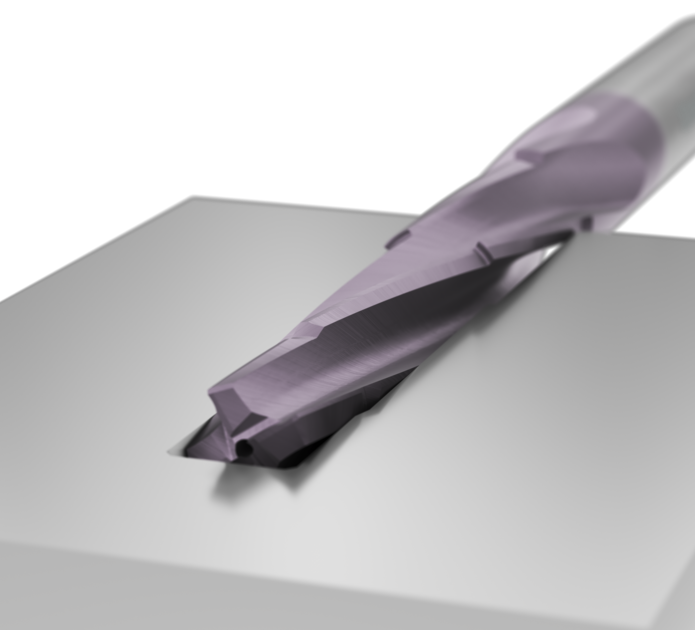

Drilling tools from Kaestner-Tools not only ensure an improvement or process-reliable maintenance of your component quality, they also contribute to the overall optimization of your processes and cost-efficiency. For bore diameters between 0.5 - 20.0 mm with bore depths 3xD to 16xD, we offer high-quality drilling tools such as twist drills, step drills, form drills and many other drill forms in solid carbide.

Optimize your subsequent machining operations on bores, e.g. for the countersinking of srews or to faciliate subsequent threading operations, with countersinks from Kaestner-Tools. For bores between Ø 0.4 - 20.0 mm, Kaestner-Tools offers you high-quality tools such as cone, flat, step or form countersinks. These tools, being ideally adapted to your machining process, support you to a high degree in achieving your production goals and specifications!

Kaestner-Tools offers many customized tooling solutions for the following types:

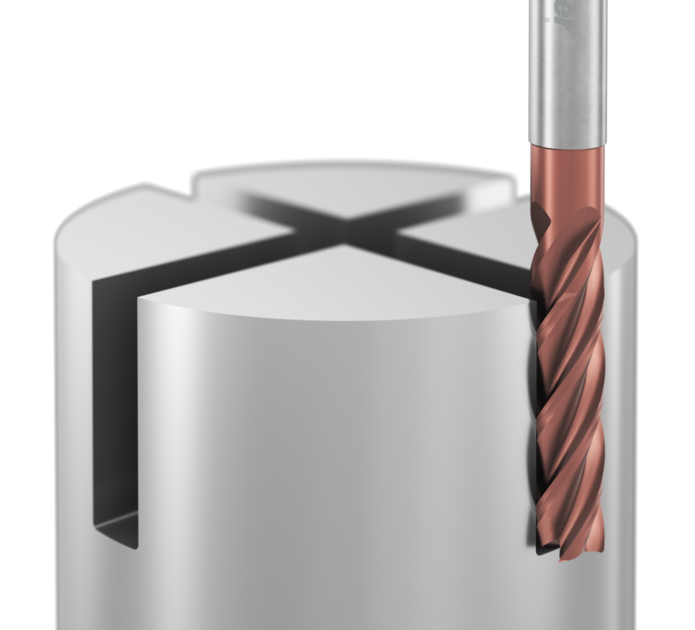

Improve the surface quality, the shape and dimensional accuracy of your workpieces as well as the process reliability of your machining. For the fine machining of your bores and shaped bores, Kaestner-Tools offers you a wide range of tooling solutions in cylindrical, stepped and shaped reamers from Ø 1 - 20 mm and in lengths up to 200 mm.

Kaestner-Tools offers many customized tooling solutions for the following types:

Kaestner-Tools offers you high-performance tools for dovetail milling, keyway and slot milling, T-slot milling as well as end mills with cutting edges for milling applications in small bores.

Apart from the standard range, the following types of milling cutters can be offered as high-quality customized solutions:

Further end mill solutions:

Versions

We offer high-performance solid carbide impact testers for impact bending tests according to DIN EN-148-1 (ISO / V or ISO / U and DVM).

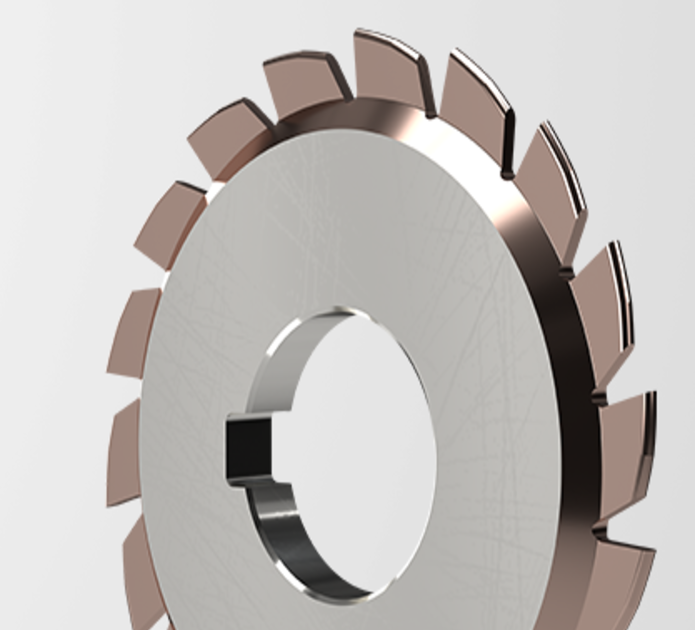

The entire form has a radial relief grinding (about 2/3 of the tooth is dimensionally stable). This allows the milling cutter to be reground in the chip space for a long time. The form only needs to be completely reset or reground when about 2/3 of the teeth in the chip space have already been reground or when the form is deformed. The milling cutters are therefore very economical.

Please note:

According to DIN 148-1 (prev. 50115) high precision with a very tight tolerance is required for notched bars. This is necessary in order for strength calculations of the tested material to be carried out correctly and precisely for statistical evidence testing. In most cases a measuring protocol of the milling cutter is required along with the provision of evidence. In order to provide this high precision to our customers and in order to meet the DIN requirements using the right tools we offer our own in-stock programme of milling cutters for notched bars (including a measuring protocol if required).

Contact us!

Our team will be happy to help you at any time.