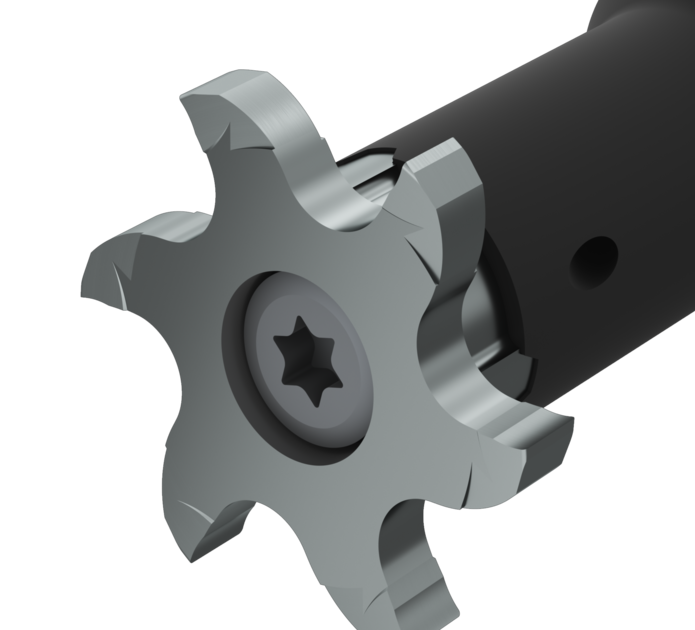

Designed and made by SIMTEK in order to meet highest expectations.

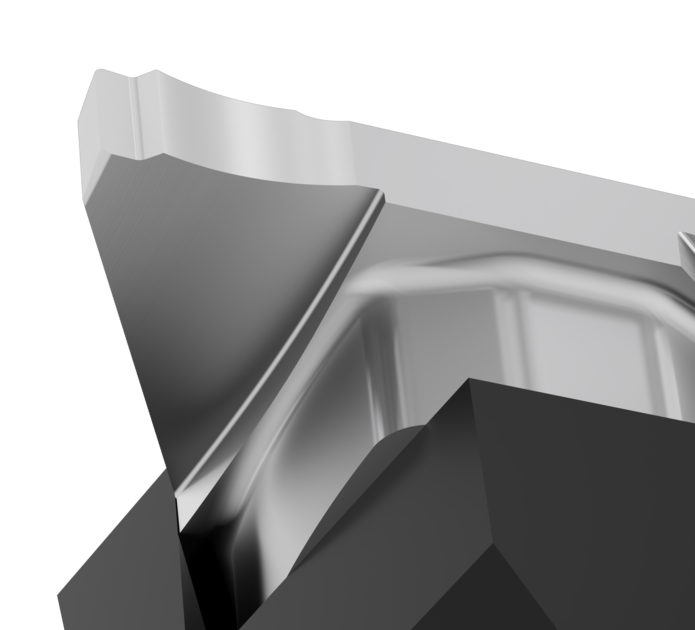

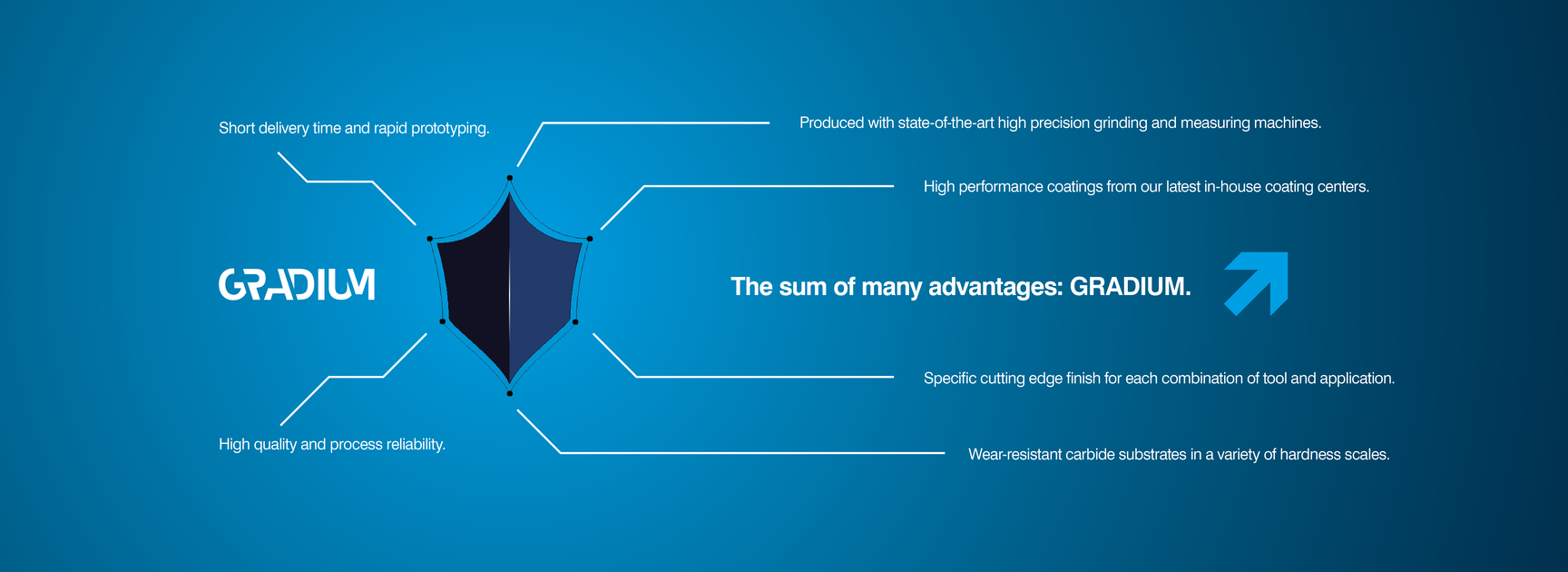

GRADIUM cutting grades stand for an ideal combination of carbide substrate, cutting edge finish and high performance coatings. They also stand for process reliability and high quality, which is one of the results of adding the coating production to the rest of the manufacturing processes we already do inhouse. This chain of manufacturing processes also provides even shorter pro-duction times and logistical advantages.

GRADIUM high performance grades: Made for your success.

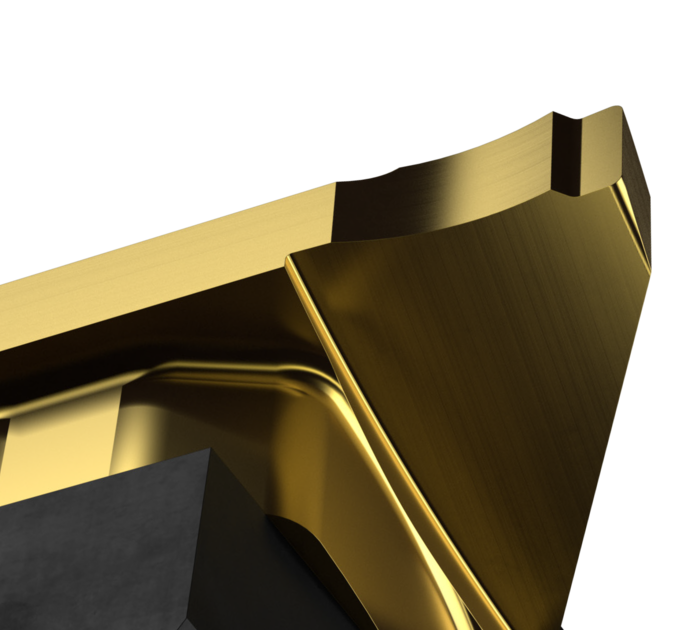

GRADIUM X8, the gold-colored all-round high-performance cutting grade, is ideally suited for successful and high-performance use of SIMTEK tools, for both turning and milling applications.

GRADIUM X8 is our first choice and suitable for use in most materials. In addition, the cutting material is characterized by the best price-performance ratio and short delivery times.

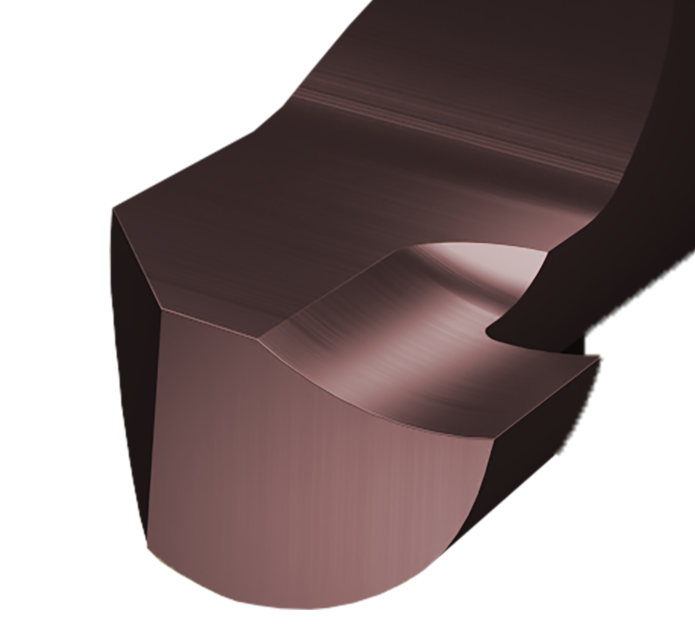

GRADIUM X4 and X6 cutting grades are ideal for turning stainless steels and non-ferrous metals. GRADIUM X4 is typically optimized for tool systems and applications with low to medium feed rates, while GRADIUM X6 is typically suitable for tool systems and applications with medium to high feed rates.

GRADIUM X5 is a special cutting grade designed for machining stainless steels and steels up to 70 HRC. GRADIUM X5 is suitable for both turning and milling applications.

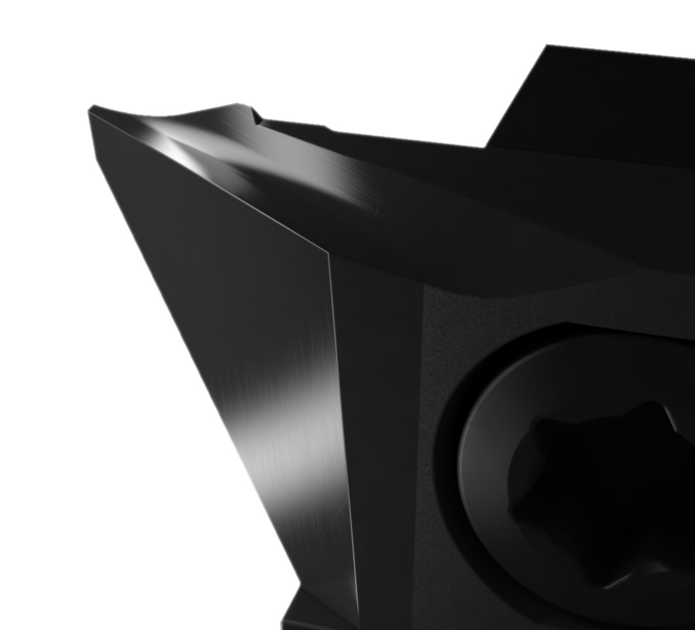

GRADIUM X7 is our special cutting grade with maximum performance for milling applications. It is ideal for alloyed and unalloyed steels.

The special cutting grade GRADIUM X1 is optimized for machining non-ferrous metals and can be used for both milling and turning applications.

GRADIUM X3 is a special cutting grade that is particularly suitable for machining iron metals. It is equally suitable for turning and milling applications.

Contact us!

Our team will be happy to help you at any time.