With the reconditioning service, you can have your high-performance tools from Kaestner-Tools reconditioned in the original geometry and with the original coating and thus benefit longer from the manufacturing advantages of each tool.

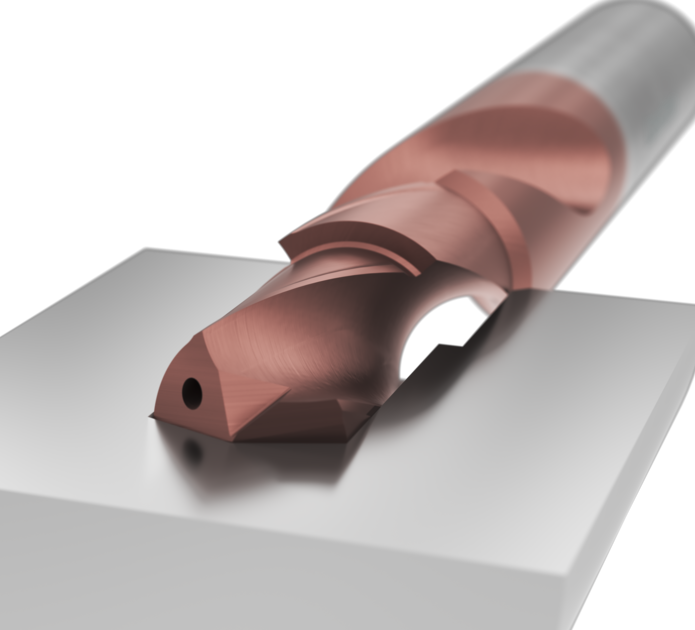

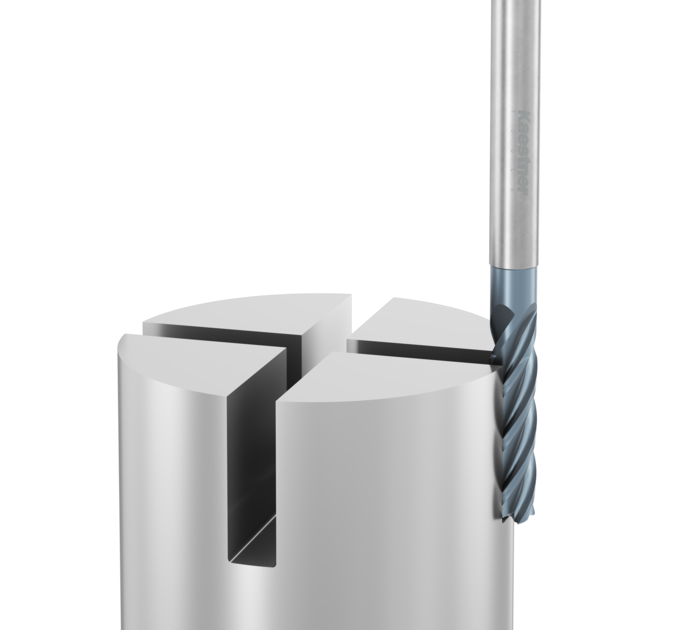

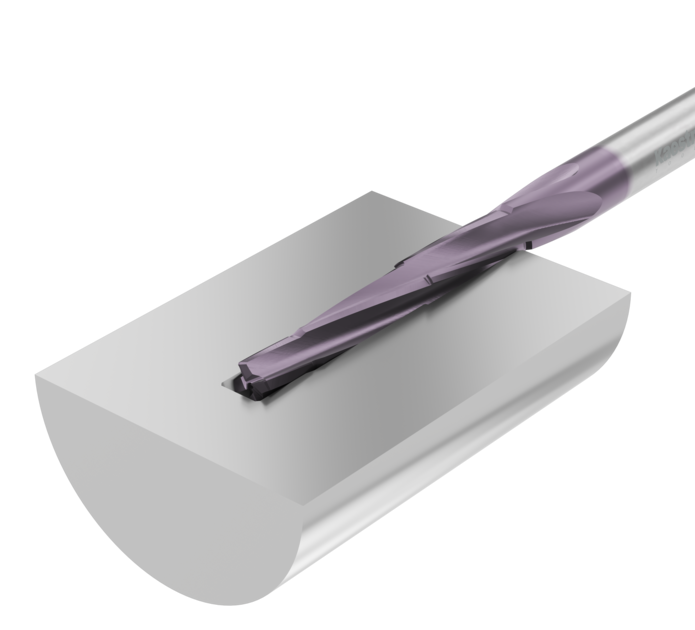

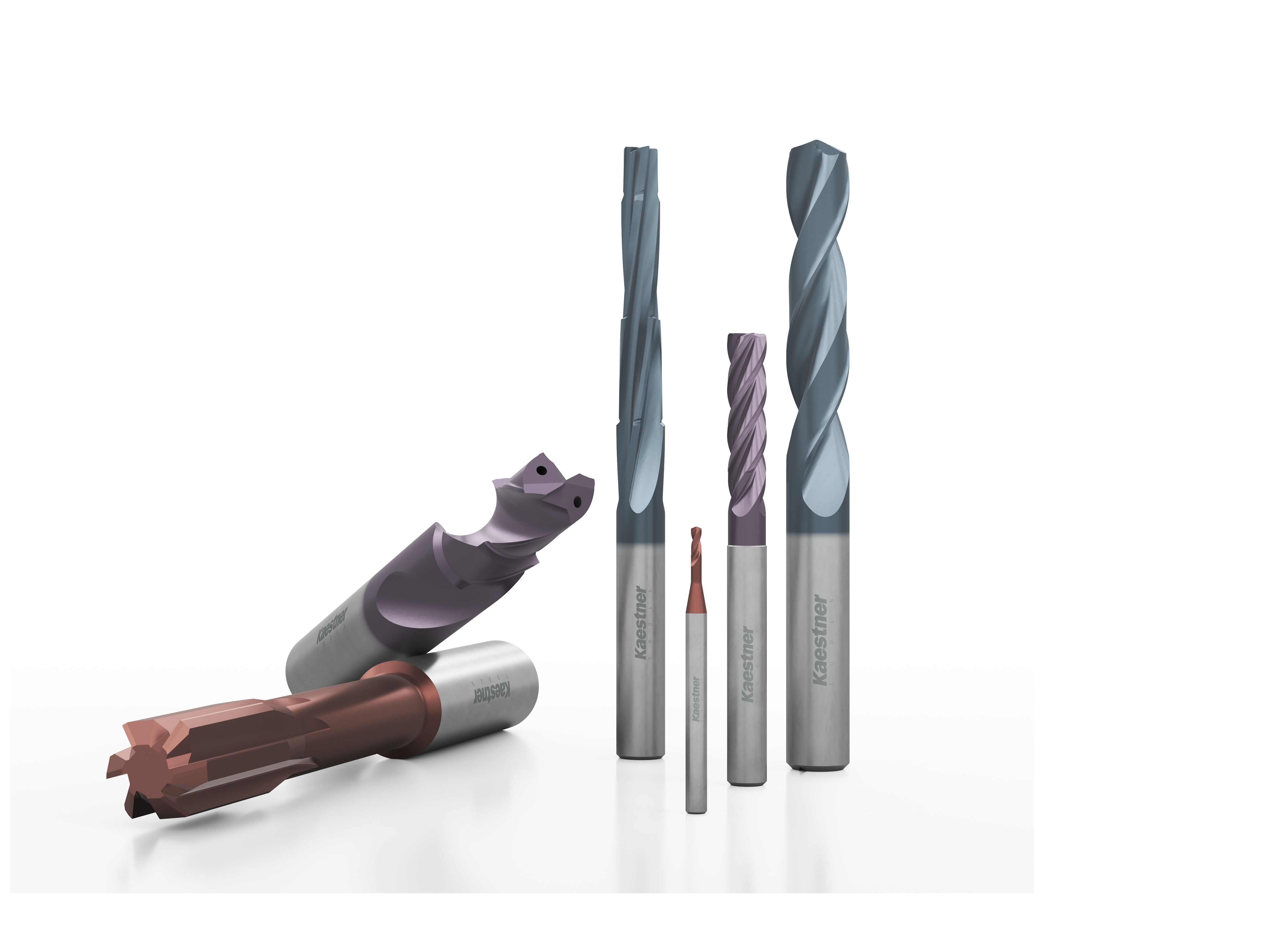

The brand Kaestner-Tools stands for high-performance tools for drilling, countersinking, reaming and milling since more than 30 years. Especially in the field of customized tools solutions, Kaestner-Tools precision tools convince with highest performance, efficiency and process reliability.

You can have your Kaestner-Tools precision tools reconditioned directly by the original manufacturer. We will regrind your tools with the original geometry and recoat the tools with their original high-performance cutting grade produced by Kaestner-Tools.

As a result, the reconditioned tools achieve a performance and tool life close to that of a new tool. In order to provide this, a state-of-the-art CNC and coating machines as well as latest measuring technology are used and can therefore guarantee you the highest quality, precision and dimensional accuracy.

The reconditioning of your Kaestne-Tools precision tools helps to save valuable resources by reducing the need of a complete new manufacturing process. As the material wear of a cutting tool is extremely low compared to the total material input, the greater part of the material used within the tool can be thus reused in a resource-saving manner. In comparison to a complete new manufacturing process, the process of reconditioning also requires much less energy.

The use of reconditioned tools significantly reduces you tool purchasing costs and also your tool stock, leading to a reduction of inventory costs. As the reconditioning process is also considerably faster compared to a new manufacturing process, you can as well increase your productivity and reduce or even avoid downtimes.

Contact us!

Our team will be happy to help you at any time.