SIMTEK stands for high quality carbide precision tools with high performance ability.

The standard range of tools includes around 11.000 tools for various applications such as grooving, turning, milling, reaming, countersinking, broaching, thread whirling and polygon milling applications. The range starts with small part machining tools for applications in bores as of Ø 0,3 mm (0.012“) and goes up to multirow, highly complex disc milling cutters with a diameter of 200 mm (7.875“).

At SIMTEK we think beyond the limits of the standard range.

We work hard and with passion to develop the best possible tooling solution for every application and the individual requirements of our esteemed customers.

Benefit from the advantages of SIMTEK individual tools, e.g. when it comes to chip control, processing speed or difficult space conditions.

Optimum machining conditions at any time, reducing non-productive time, avoiding 100% controls: there are many reasons to ensure optimum chip control in series production.

Find out how to enable maximum chip control and increase the process reliability and machining efficiency.

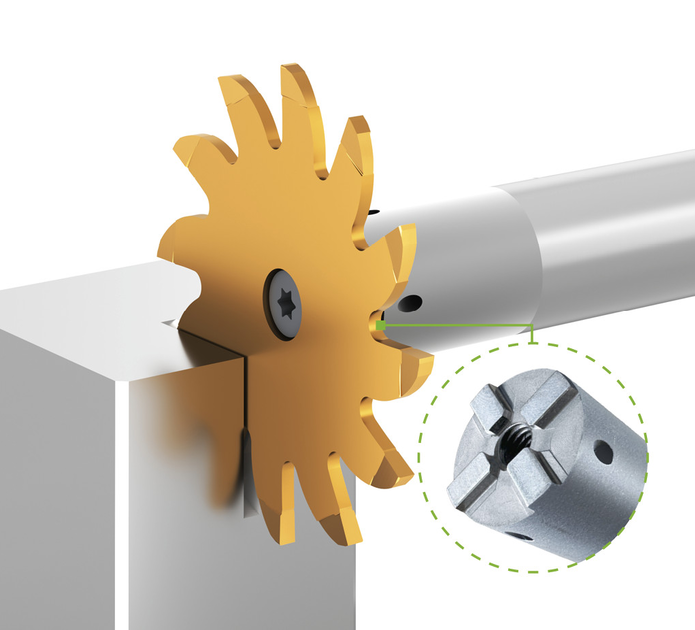

simmill 9W closes the existing gap between modular milling systems and monoblock tools because, despite its modular design, simmill 9W comes very close to the performance of monoblock tools - at significantly lower tool costs.

Discover simmill 9W, the robust system with up to 12 cutting edges for slotting, parting and slitting with milling depths of up to 16,5 mm!

Increasing process reliability. Reducing process times. Lowering cutting costs. The success of our customers in the most diverse machining tasks is in our DNA.

Get to know SIMTEK and discover high performace products and the passionate people behind.

Find out more about SIMTEK

At SIMTEK we use all our strength and ambition to offer optimal tooling solutions designed to meet the individual requirements and expectations of our customers. In doing so, we follow an uncompromising path with regard to the quality of our products as well as our services.

In addition to our claim to be able to offer the best possible tooling solution in terms of quality, we also strive to provide our customers with the greatest possible economic benefit for cost-efficient component production.

The certified quality management according to ISO 9001:2015 is part of our company processes and thus ensures a consistently high level of quality.

Use the SIMTEK Toolfinder and find the right tooling solution for your application.

Just enter your needed paramater such as machining method or application and with just a few mouse clicks you get the right solution from around 11,000 standard tools.

Contact us!

Our team will be happy to help you at any time.