SIMTEK offers you efficient tool solutions for the manufacturing of gears, e.g. according to DIN 3972, DIN 867 or ISO 53. SIMTEK relies on precise and flexible modular milling systems and disc milling cutter or milling cutter with multiple insert seats, which are optimally adapted to the gear to be produced and coated with our own high-performance cutting grades.

This increases the efficiency of gear production for modules 0.5 to 8.0 and ultimately optimizes production costs.

Profile milling is a precise method for manufacturing gears and is particularly suitable for small to medium batch sizes. The tooth profile is created by the specific shape of the tool cutting edges. This makes it possible to manufacture gears flexibly and reliably on conventional lathes or milling machines without special coordination between the tool and workpiece movements.

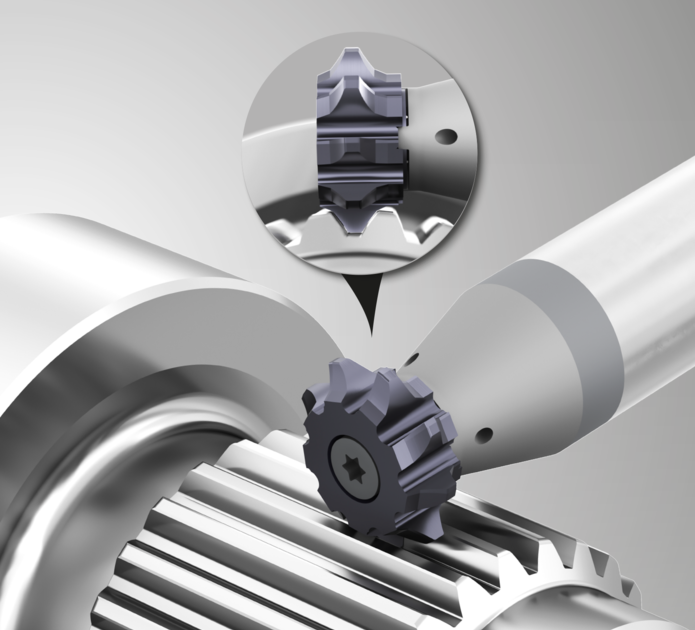

Milling of a straight-toothed spur gear with the high-performance modular milling system simmill 9W. Thanks to its toothing technology, simmill 9W is ideal for the efficient and reliable manufacturing of gears.

Contact us!

Our team will be happy to help you at any time.