The standard range of tools includes around 11.000 tools for various applications, combined in the product groups simturn, simmill, simcut Kaestner-Tools.The range starts with small part machining tools for applications in bores as of Ø 0,3 mm and goes up to multirow, highly complex disc milling cutters with a diameter of 200 mm.

Use the SIMTEK Toolfinder and find the right tooling solution for your application.

Just enter your needed paramater such as machining method or application and with just a few mouse clicks you get the right solution from around 11,000 standard tools.

Optimum machining conditions at any time, reducing non-productive time, avoiding 100% controls: there are many reasons to ensure optimum chip control in series production.

Find out how to enable maximum chip control and increase the process reliability and machining efficiency.

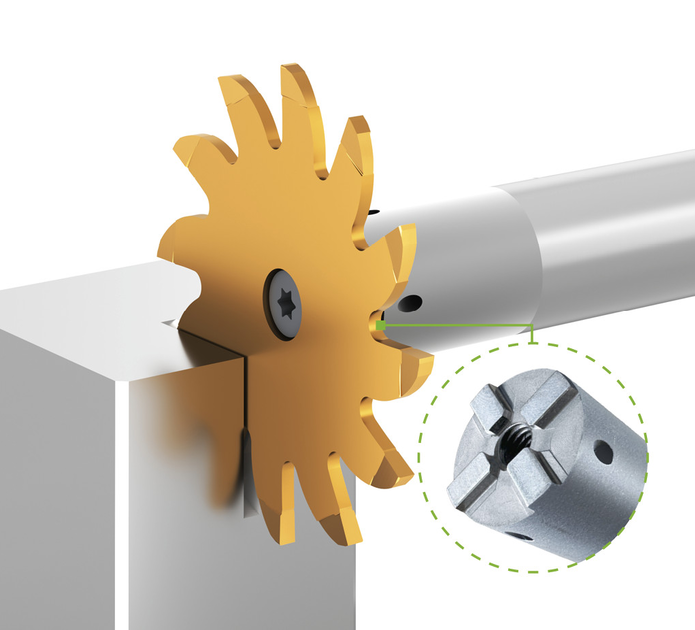

simmill 9W closes the existing gap between modular milling systems and monoblock tools because, despite its modular design, simmill 9W comes very close to the performance of monoblock tools - at significantly lower tool costs.

Discover simmill 9W, the robust system with up to 12 cutting edges for slotting, parting and slitting with milling depths of up to 16,5 mm!

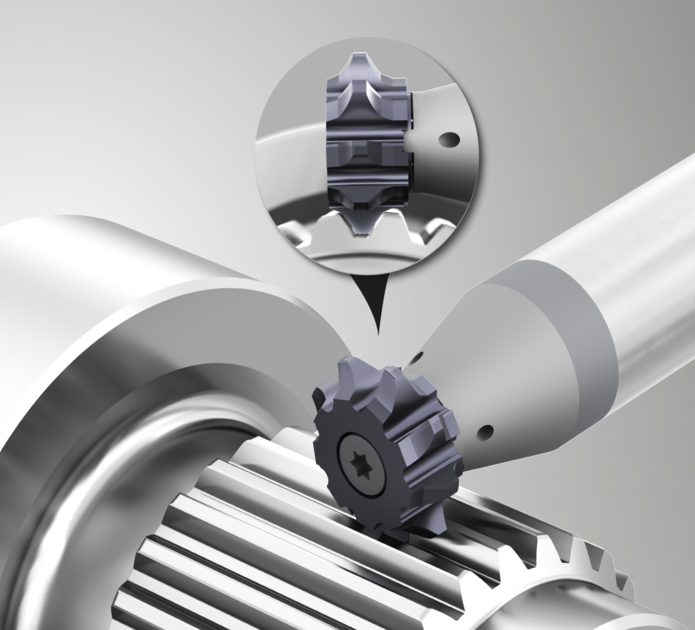

SIMTEK offers you efficient tool solutions for the manufacturing of gears, e.g. according to DIN 3972, DIN 867 or ISO 53. SIMTEK relies on precise and flexible modular milling systems and disc milling cutter or milling cutter with multiple insert seats, which are optimally adapted to the gear to be produced and coated with our own high-performance cutting grades.

At SIMTEK we think beyond the limits of the standard range.

We work hard and with passion to develop the best possible tooling solution for every application and the individual requirements together with our esteemed customers.

Contact us!

Our team will be happy to help you at any time.