At SIMTEK, a team of experienced tool designers works hard and with passion to develop the best possible tooling solution for each of your applications. The main focus is always on optimally designing the quality and performance features as well as achieving the best economic efficiency for you. This leads to the need to think beyond standard tools.

Contact us and benefit from our great experience of thousands of successful custom-made individual tools.

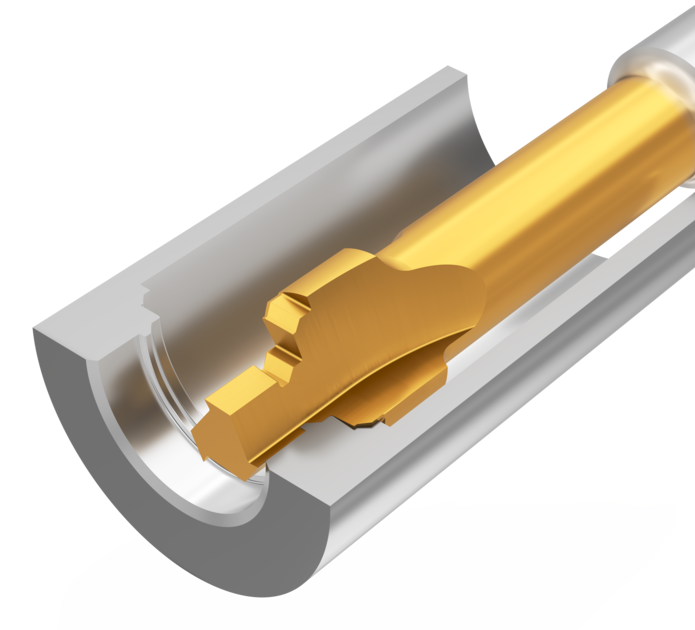

Maximum chip control with lasered chip forming geometries

The use of 3D-lasered chip forming geometries increases the process reliability and cost-effectiveness of your machining. In addition, complex requirements and combination tools can be implemented cost-effectively with 3D-lasered chip forming geometries.

The image shows the boring of a bore with a 3D-lasered chip forming simturn DX geometry.

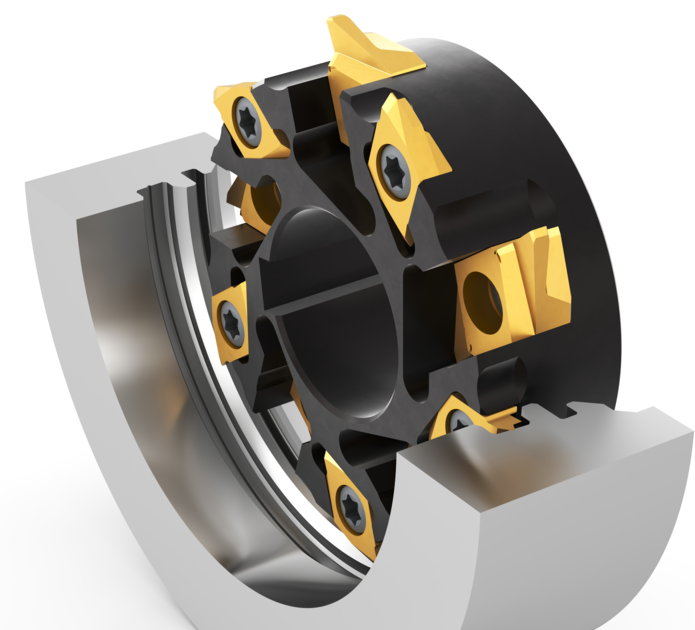

Combined milling cutter

Machining time is reduced thanks to a perfectly coordinated double milling tool. Precise radial and axial runout is ensured by tightest tolerances.

Thanks to cutting edge widths of up to 17,4 mm (0.685") and a compact design, simmill KX can be used for a wide variety of internal and external milling applications with a high number of teeth.

Complete contour milling with simmill AX

High process reiliability due to chip control and secure evacuation of the chips, reducing production down time. Therefore, the complete contour can be machined without any interruptions.

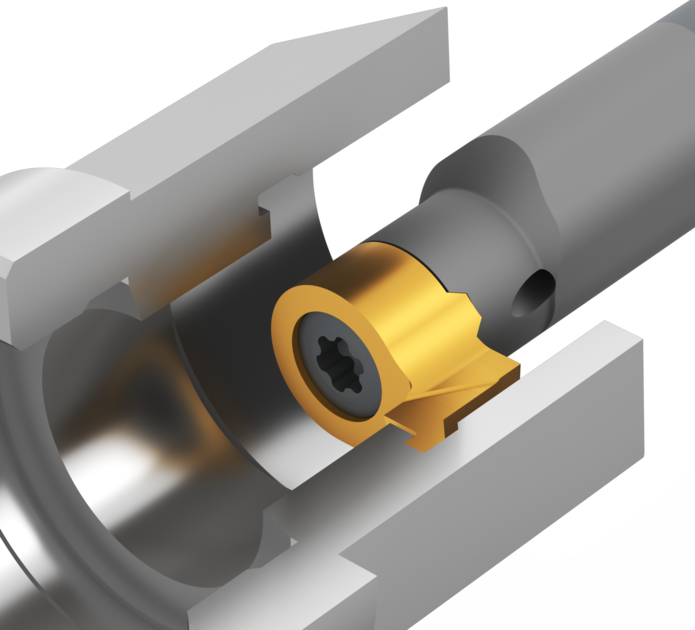

Axial groove in narrow bore

Axial groove in a narrow bore with simturn DX cutting tool, perfectly adapted to the interfering contour.

The precision-ground simturn DX inserts are available in 15 different sizes for almost every application in bores between Ø 7,0 mm (0.275") and approx. 24,0 mm (0.945").

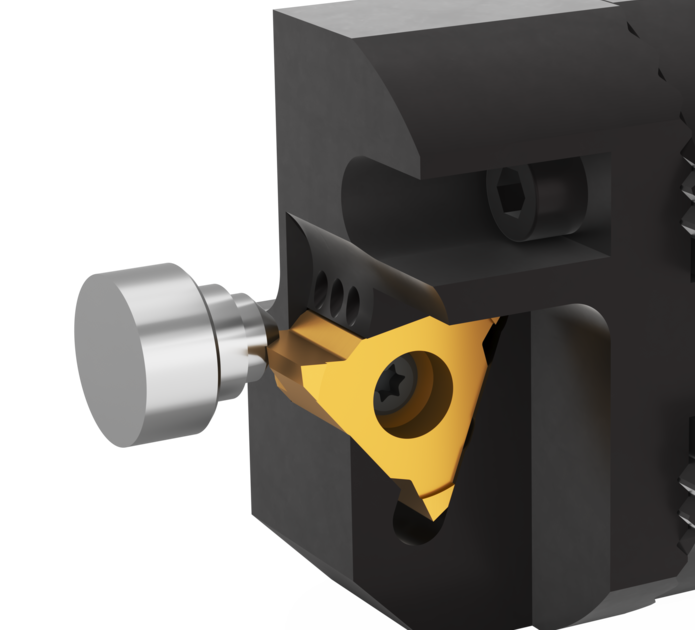

Customer specific toolholder for use on rotary transfer machines

Modular toolholder for use on rotary transfer machines. High-precision radial adjustment possibility enables maintainance of highest manufacturing tolerances.

advantages of SIMTEK individual tools for your component machining.

Our team of experts will be happy to assist you at any time and work with you to develop the best possible tooling solution for your application.

Use the SIMTEK Toolfinder and find the right tooling solution for your application.

Just enter your needed paramater such as machining method or application and with just a few mouse clicks you get the right solution from around 11,000 standard tools.