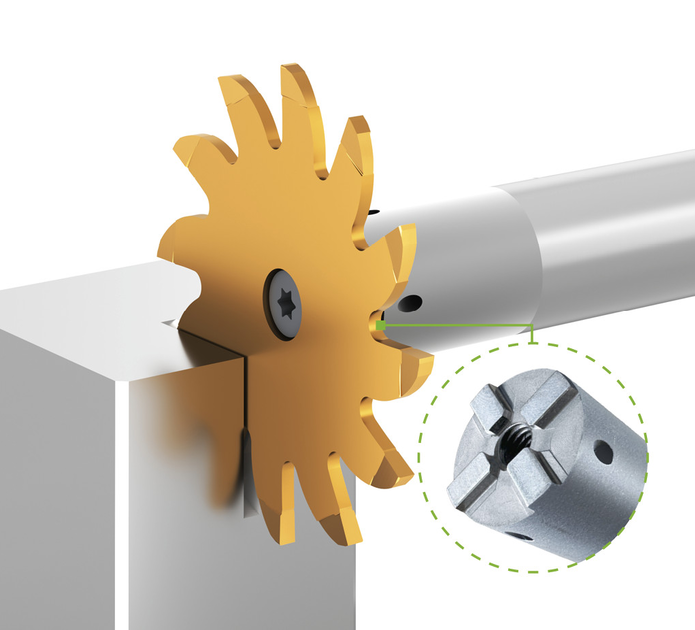

Our revolutionary system combines the best of two worlds. It combines the advantages of a monoblock tool with the cost-effectiveness of a modular tool system. This means maximum stability and precision – with complete flexibility.

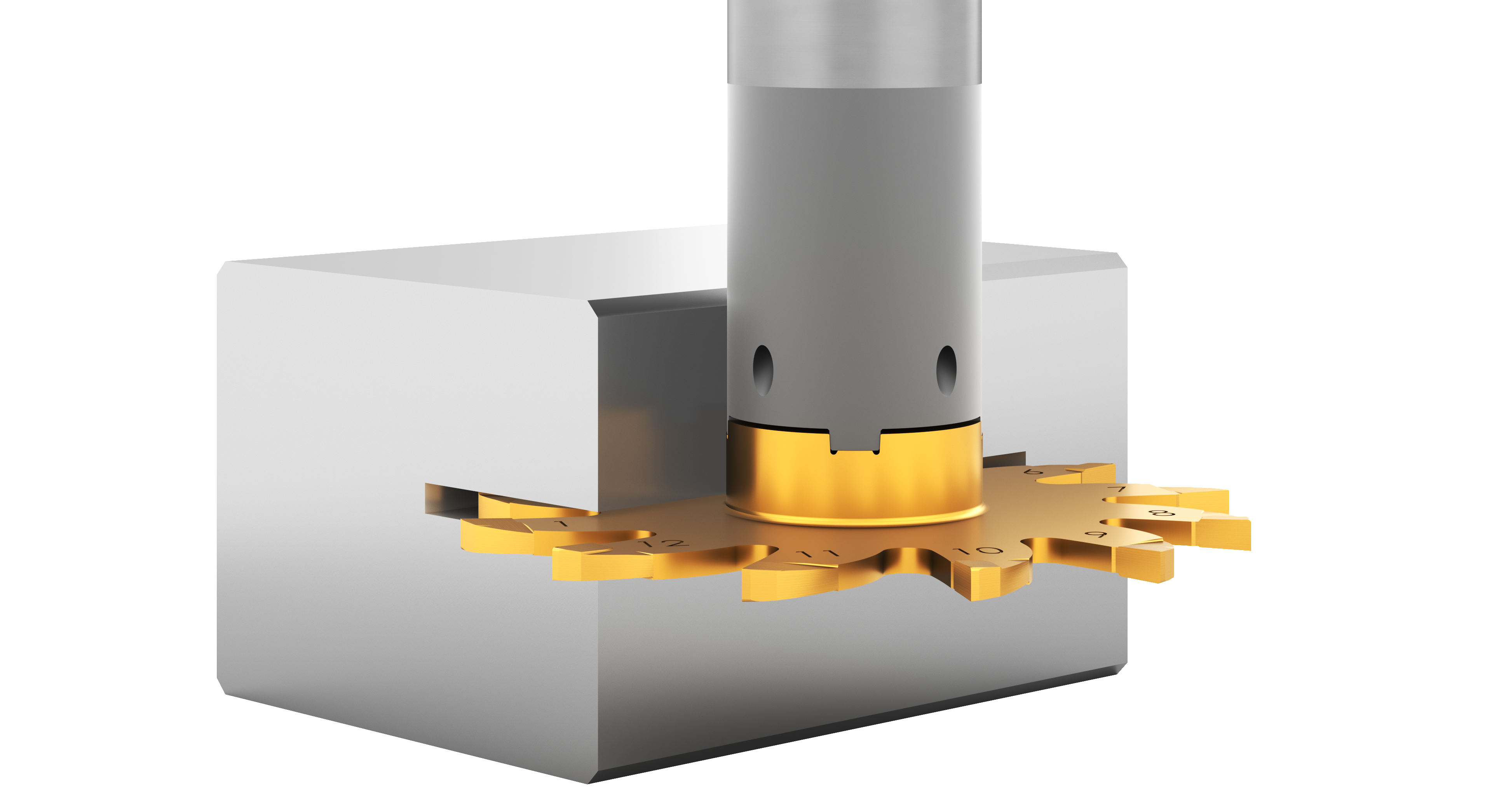

Discover simmill 9W, the robust system with up to 12 cutting edges for slotting, parting and slotting with milling depths of up to 16.5 mm (0.650")!

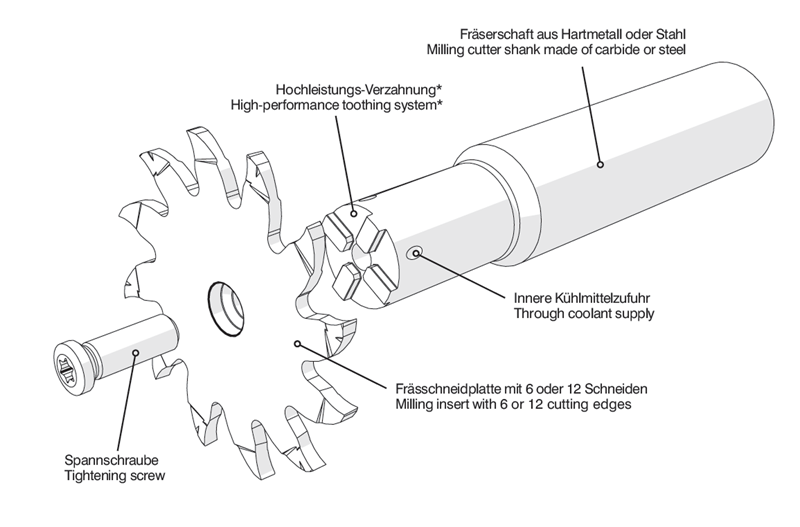

The high-performance toothing ensures optimal power transmission at high torques and a long service life with maximum flexibility.

Would you like to learn more about simmill 9W?

Request a free expert consultation.

The table compares different types of tooling systems and helps to categorize the simmill 9W tooling system.

PSUV** |

4PSUV** |

simmill 9W |

Monoblock*** |

|

|

Toothing |

sintered |

ground |

ground high-performance |

|

|

Surcharge per cutting edge* |

+0 € |

approx. +6 € |

approx. +12 € |

more expensive |

|

Power transmission |

+ | ++ | +++ |

++++ |

| Holder wear | + | +++ | +++ | / |

| Radial run-out | 0,03 mm | 0,015 mm |

0,015 mm |

|

| Axial run-out | 0,03 mm | 0,015 mm |

0,015 mm |

|

|

Diameter Teeth |

up to 40 mm 6 teeth |

up to 40 mm 6 teeth |

up to 63 mm 12 teeth |

no limit |

| Regrinding | no | no | yes | yes |

*Indicative price point. Actual prices may vary.

**Designates SIMTEK standard and customized tools in the PMX, PX, SX, UX, VX, 4U and 4V families with cutting circle diameters from 6.7 mm to 39.7 mm.

***Refers to market-standard monoblock tools with comparable cutting circle diameters to simmill 9W tools.

Tools from the modular simmill 9W tool system have similar performance characteristics to monoblock tools and are designed for machining with high torques, feed rates and cutting depths.

For machining companies, this means: maximum precision with more flexibility

Similar to monoblock tools, the simmill 9W tool system offers outstanding concentricity and axial run-out properties for precise machining at low manufacturing tolerances.

The modular design enables a cost-efficient replacement of worn cutting inserts, while the precision-ground teeth ensure a long service life for the holders. For machining companies, this means lower tool costs combined with maximum precision and performance.

Durable and robust: The close manufacturing tolerances used to produce simmill 9W tools make the holders particularly robust and ensure a long service life even under difficult conditions.

|

Milling inserts:

|

|

Carbide:

Steel:

|

|

|

Milling inserts:

|

|

Carbide:

Steel:

|

|

Modular meets monoblock:

The Best Of Both Worlds

This white paper explains

a) the advantages of simmill 9W tools over conventional circular milling systems and

a) how you can save costs by using them without having to compromise on the performance features of monoblock tools.

Contact us!

Our team will be happy to help you at any time.